Products

Thin Film Evaporator

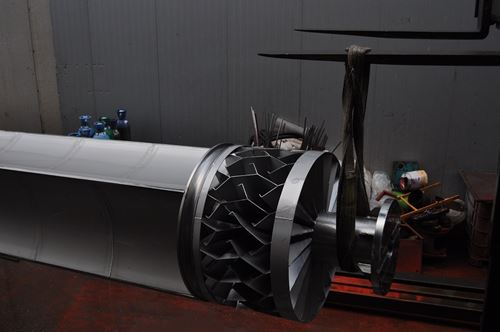

Thin film evaporators are a specialized type of evaporator designed for the precise and efficient evaporation of heat-sensitive liquids and solutions. The evaporation process takes place by spreading the liquid in a thin film over a heated surface.

THİN FİLM EVAPORATÖR

Thin Film Evaporator (TFE)

TFEs allow the product, which passes through indirect heat transfer and mechanical mixing, to be separated from the less volatile components of the volatile components in a controlled manner. TFEs are the most difficult separation processes.

Provides professionally performing solutions. The TFEs consist of a rotor mounted inside the evaporation roller. The liquid passing through is plastered on the heated surface and distributed uniformly.

Properties

• Very short processing time for heat sensitive

• Prevention of product spoilage thanks to evaporation with a single pass

• Minimizing the accumulation of sediment on the heat transfer surface by mixing the liquid film properly.

• 1 mBar working pressure and operating temperature up to 400 ° C

Usage areas

• Vacuum distillation of sensitive chemicals, glycols, waste oils, fatty acids and derivatives, rubber chemicals, amines and esters

• In the processes of oleo resins and vegetable extracts

• Purification of dirty solvents

• Bio diesel and glycerin purification

• In condensing products that tend to foam

English

English